Taiwan Greige Fabrics & Woven Fabrics Manufacturer | U-long

Located in Taiwan since 1983, U-Long High-Tech Textile Co., Ltd. has been a textile and fabric manufacturer. Their main fabrics and textiles, include high tenacity yarns, industrial and complementary textiles, sustainable and biodegradable textiles, knitted fabrics, woven fabrics and functional fabrics, especially for the functional fabrics, hyperbreeze, 3D structure, anti-odor and durable fabrics are U-long's specialties.

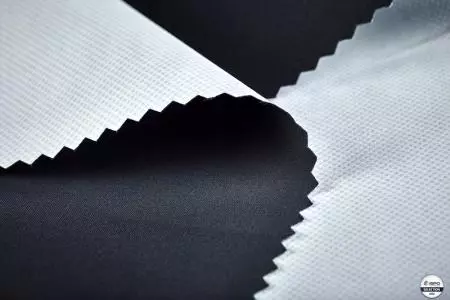

U-LONG was established in 1983 as a core enterprise of Nam Liong Group. Originally founded to produce special industrial fabrics, the company gradually expanded into the field of high-value stretch fabrics through cutting-edge research and development. As being Taiwan largest, greatest and most professional woven stretch manufactory, U-LONG continuously imports diverse advanced computerized manufacture facilities and employs professional specialists. The finished fabric are for various applications including Apparel (Function & Fashion), Bags (Luggage), Shoes, Industrial use, Protection use, and Home textile.

U-long has been offering customers high-quality fabrics and textiles since 1983, both with advanced technology and 48 years of experience, U-long ensures each customer's demands are met.